Materials Characterisation Lab

Description

In the Materials Characterisation Lab, we characterise the mechanical properties of materials and components to optimise designs, improve durability and strength, and increase sustainability.

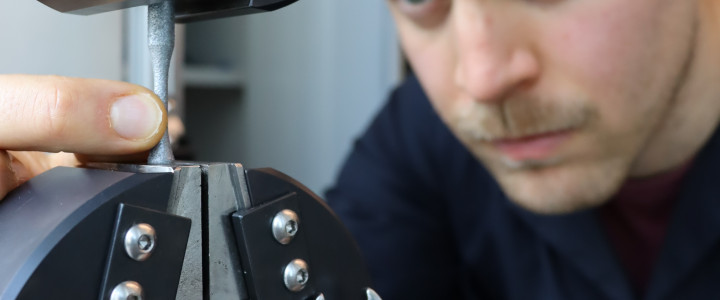

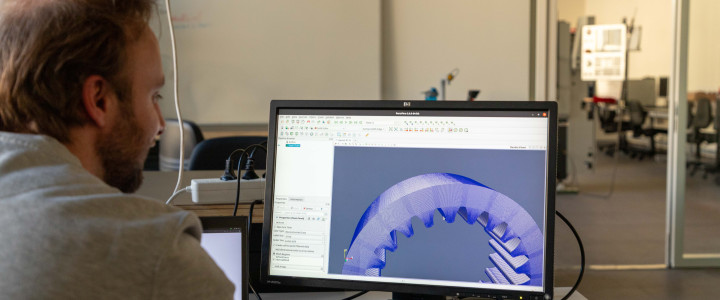

The Materials Characterisation Lab focuses on investigating the behaviour of metals, concrete, polymers and fiber-reinforced composites, including materials for 3D printing and additive manufacturing. The laboratory is equipped for tensile, compression, bending and punching tests, high- and low-cycle fatigue tests, as well as for tests at high temperatures. As well as specimens, testing is carried out on a wide range of components, including gears (bending fatigue, wear and efficiency), bearings (lubrication analysis) and sports equipment (design optimisation of skis and ski rollers). In-house metallography allows the analysis of fracture surfaces, while advanced numerical (e.g. FEM and CFD) and experimental techniques (e.g. DIC) are used to develop and calibrate material constitutive laws, damage models and lubricant behaviour..

The laboratory provides materials expertise for the design of mechanical components. Companies and research institutions wishing to carry out research projects of specific interest can benefit from the skills of the laboratory's staff and/or its equipment by entering a research contract.

Research topics

- Mechanical characterisation of materials: metals, concrete, polymers and fibre-reinforced composites, including materials for 3D printing and additive manufacturing. They can be characterised in terms of tensile, compression and bending behavior, under both quasi-static and dynamic conditions. For the latter, both high and low cycle fatigue properties can be investigated. Stamping tests to characterise fibre reinforced materials are also available.

- Mechanical characterisation of polymer gears and metal microgears, which can be tested in both meshing and single tooth bending configurations. Bending fatigue, efficiency and wear characteristics of gears can be characterised and validated by FEM analysis.

- Analysis of lubrication efficiency in bearings, using a dedicated test rig and advanced CFD analysis.

- Mechanical analysis and design optimisation of sports equipment (e.g. skis and skirolls).

images

Equipment

Equipment and technologies

- MTS Criterion 45 tensile machine (100 kN load capacity, 1220 mm stroke): quasi static traction and compression tests, bending tests, punch tests, high temperature tests.

- STEP-LAB UD04 tensile machine (5 kN load capacity, 500 mm stroke): quasi-static tension and compression tests, dynamic (up to 35 Hz) tension and compression high and low cycle fatigue tests. Tests on small module gears.

- Gear test bench (rpm range 500-4000 rpm, torque up to 10 Nm, adjustable centre distance 20-150 mm). Meshing gears tests with parallel and orthogonal axis configurations, thermal tests up to 300 °C and with thermal camera.

- Bearing test bench for lubricant flow tests aeration analysis, as well as velocity field measurements using Particle Image Velocimetry. Modular design adaptable to different bearing types, with outer diameters up to 130 mm. Load independent power losses measurable in axially loaded (up to 6 kN) rolling element bearings.

- Hardness and micro-hardness testers and full range of equipment needed for metallographic sample analysis. Taylor Hobson Talysurf profilometer for roughness measurements. Digital Image Correlation analysis camera.

Main projects

The research group is involved in multiple international research projects, some examples:

- COST project CA23109 - Fatigue Benchmark Repository (FABER)

- H2020 CleanSky2 - Innovative Design for Reliable Planet Bearings (IDERPLANE)

- Seal of Excellence - An adaptive concurrent multi-scale method for modeling wear (WEAR)

- Joint Projects D-I EG2259 - Miglioramento della previsione della cinematica dei cuscinetti volventi grazie all'accurata considerazione delle forze idrauliche (INERTIAS)

text

People

Laboratory Head: Franco.Concli

Team: Lorenzo Maccioni, Lorenzo Fraccaroli, Lorenzo Pagliari

Room: BZ N - B1.0.06

Contact: mcl@unibz.it